Researchers at the University of Illinois, US, have made inks that can print tiny three-dimensional patterns using metal oxides. The inks could allow fast, easy printing of micro-fuel cells, sensors and photonic crystals, the scientists say.

Using conventional lithographic techniques to make three-dimensional structures is time consuming because it requires a template to be made for each layer. But the new inks dry almost instantly in air - even as they bridge gaps in the layers below. A robotic arm delivers the ink, automatically printing as many layers as necessary while dramatically cutting the manpower required.

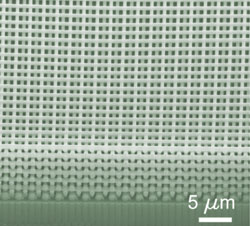

Complex 3D structures on a sub-micron scale can be easily printed with the team's new inks

© University of Illinois, 2007

|

The team's first sol-gel inks are highly concentrated solutions of a titanium alkaloid complex, which solidify in air and maintain the printed shape. They heated the ink to around 700°C, which causes the titanium complex to calcinate and form titanium oxide (TiO2).

Jennifer Lewis, professor of materials science and engineering at Illinois and co-author of the paper, says the team has made features as small as 225 nm. 'Our technique offers unparalleled resolution for 3D patterning of oxide structures,' Lewis told Chemistry World. 'This opens up a new avenue to printed photonic, electronic and energy materials.'

Commenting on the work, Mark Welland, director of the Cambridge Nanoscience Centre, told Chemistry World, 'Scalability has been the bugbear of nanotechnology for a long time. Useable, economically viable manufacturing processes are an issue ... [inkjet printing] has the advantages of being very cheap, relatively fast and easy to build up layers.'

Jonathan Edwards